G

Guest

Guest

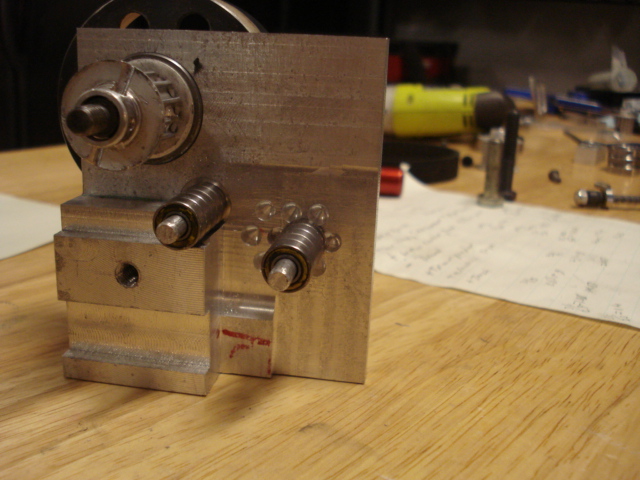

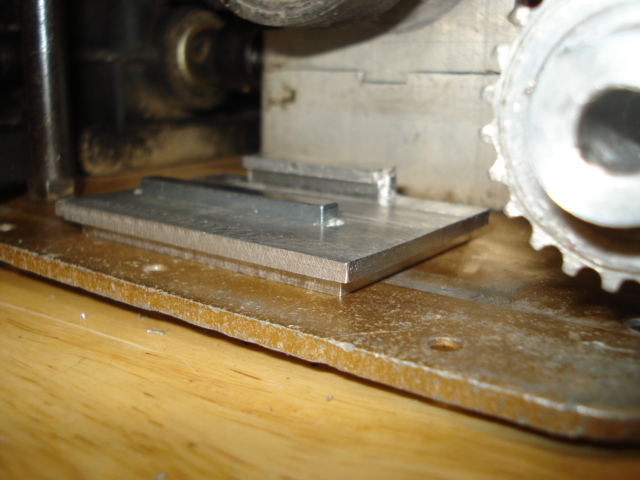

Wow... That's a big chunk of metal. Are you still going to be lighter? Looks really tough!

Welcome to RedcatRampageForum! Are you a Redcat fan? If so you're in luck as you've have arrived to the biggest and best RedcatRampage RC community.

Come join our community and ask your questions, show off your Recat RCs and share your experience!

And it's not too wise to be driving around a 35lbs missile on the street w/ no brakes

Register and gain access to Discussions, Reviews, Tech Tips, How to Articles, and much more - on the largest Redcat Rampage RC community for Redcat RC enthusiasts that covers all aspects of the Redcat brand!

Register Today It's free! This box will disappear once registered!