Deluge

Senior Member

- Messages

- 7,900

- Location

- Tucson, Arizona

Lmao! Yeah, that would be a problem.Guantanamo Joe said:Figure you could take the one from your old dryer... but Im not sure how you would keep the extension cord plugged inha ha ha

Welcome to RedcatRampageForum! Are you a Redcat fan? If so you're in luck as you've have arrived to the biggest and best RedcatRampage RC community.

Come join our community and ask your questions, show off your Recat RCs and share your experience!

Lmao! Yeah, that would be a problem.Guantanamo Joe said:Figure you could take the one from your old dryer... but Im not sure how you would keep the extension cord plugged inha ha ha

Maybe he'll come on and give some advice and/or sell me his motor. I noticed how my gearbox is much beefier than what he had several years ago. Redcat did a nice job beefing this thing up.Deluge said:I remember that build! He's a member here, too. Pretty awesome setup.

There's a big difference in gearing between 35 and 45 i.e. 10:1 vs. 13.1:1, that 30% equates to much cooler components and significantly longer run times. To to be honest, the track I was at didn't require pushing 45 mph. Being conservative on gearing is much easier to work with then starting out of the gate over geared.RCDAD said:45.. Too fast!? No way, unless you plan on just running really tight tracks. 35 is about stock speed for the gasser you just yanked out.

If your building it for the track the run times are more important than top speed.There's a big difference in gearing between 35 and 45 i.e. 10:1 vs. 13.1:1, that 30% equates to much cooler components and significantly longer run times. To to be honest, the track I was at didn't require pushing 45 mph. Being conservative on gearing is much easier to work with then starting out of the gate over geared.

You could always just change gearing to do some speed runs.As much as I want to see this thing be lightening fast, I won't be too happy having to send my esc/motor back b/c I calculated wrong.

Very true.RCDAD said:You could always just change gearing to do some speed runs.

You are correct on the acceleration. An electric motor has the same power output through the rpm range. The gas engine increases power output as you get close to the top of the rpm range. The torque is amazing on electric.mulepic said:Very true.The more I look into the clutch approach as shown in the pusher bike video the more I like it. It should act just like a gas motor but w/ much better low end acceleration b/c I could imagine the brushless motor spinning up faster than the gas engine but I'm just speculating based off of what I see in videos.

Most engines don't come with the clutch bell. It is a Redcat specific part.A question about selling the gas engine. Can I keep the clutch when I sell it? I'm thinking that clutch and bell housing is specific to redcat, right?

Thanks. Can I keep the clutch i.e. the shoes and the thing they mount to? So the only thing sticking out of the engine is the crankshaft. I guess I'll have to take a picture of it.RCDAD said:Most engines don't come with the clutch bell. It is a Redcat specific part.

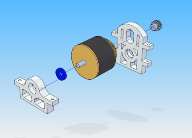

You can keep the clutch. The clutch bell is specific to Redcat.mulepic said:Here's is roughly the motor I'm considering. I needs to handle 12s and be around 400kv. I'll run it on 10s though. I just wish I could find something comparable in the US for faster shipping and/or a store I've purchased from before. Does anyone have any experience w/ leaderhobby.com?https://www.leaderhobby.com/product.asp?ID=9394001226071&Location=HK

A question about selling the gas engine. Can I keep the clutch when I sell it? I'm thinking that clutch and bell housing is specific to redcat, right?

You can keep the clutch plate, as well.mulepic said:Thanks. Can I keep the clutch i.e. the shoes and the thing they mount to? So the only thing sticking out of the engine is the crankshaft. I guess I'll have to take a picture of it.The reason being is b/c it's looking promising to simply mount the clutch assembly to the electric motor. And leave the pinion mounted to the clutch bell.

Register and gain access to Discussions, Reviews, Tech Tips, How to Articles, and much more - on the largest Redcat Rampage RC community for Redcat RC enthusiasts that covers all aspects of the Redcat brand!

Register Today It's free! This box will disappear once registered!