Dongskie

Senior Member

- Messages

- 120

- Location

- Mandaluyong City

I'll try out a belt and one way bearing for the meantime... I'll post some mock-ups

Welcome to RedcatRampageForum! Are you a Redcat fan? If so you're in luck as you've have arrived to the biggest and best RedcatRampage RC community.

Come join our community and ask your questions, show off your Recat RCs and share your experience!

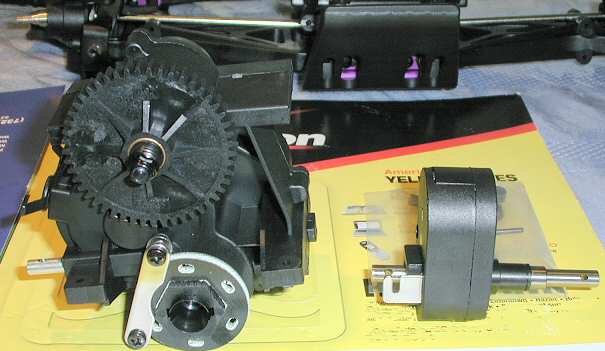

What model has this sliding gear?Dongskie said:HPI made a reversing gearbox with a sliding gear and a 3rd servo.

HPI Savage, its a separate module taht has to be installed inside the existing gearbox of the MT..RampageHopUps said:What model has this sliding gear?

that's good....ika said:we can attach pulley to any diff gear's axle and install motor above,than connect by belt.

and ESC is required for the 3rd channel and a power source..ika said:what activating 3th channel, how to power motor?Is it possible to connect ESC to channel 3 and operate at constant load?

Problem is the size, I don't think that exists small enough to fit in rc.robygon said:What about a belt drive motor with a magnetic engagement pulley like the one on the automotive air condition compressors. Some people call it a magnetic clutch.

I was thinking about using the same exact gear that goes 90 degrees into the center drives. I haven;t read a manual in a long time, but add another gear opposite the brakes,Dongskie said:I think that's a great idea... I just need to think how to couple it to the drivetrain

Its raining real bad now. I guess Saturday will be Redcat day.RampageHopUps said:Yes, I agree for the home made versions, the pulleys are easier. For a machine shop version, the gear would certainly be cheaper. If it rains this weekend, I will fool around with some ideas.

Register and gain access to Discussions, Reviews, Tech Tips, How to Articles, and much more - on the largest Redcat Rampage RC community for Redcat RC enthusiasts that covers all aspects of the Redcat brand!

Register Today It's free! This box will disappear once registered!