Well, ...Vader actually, but what's in a name...

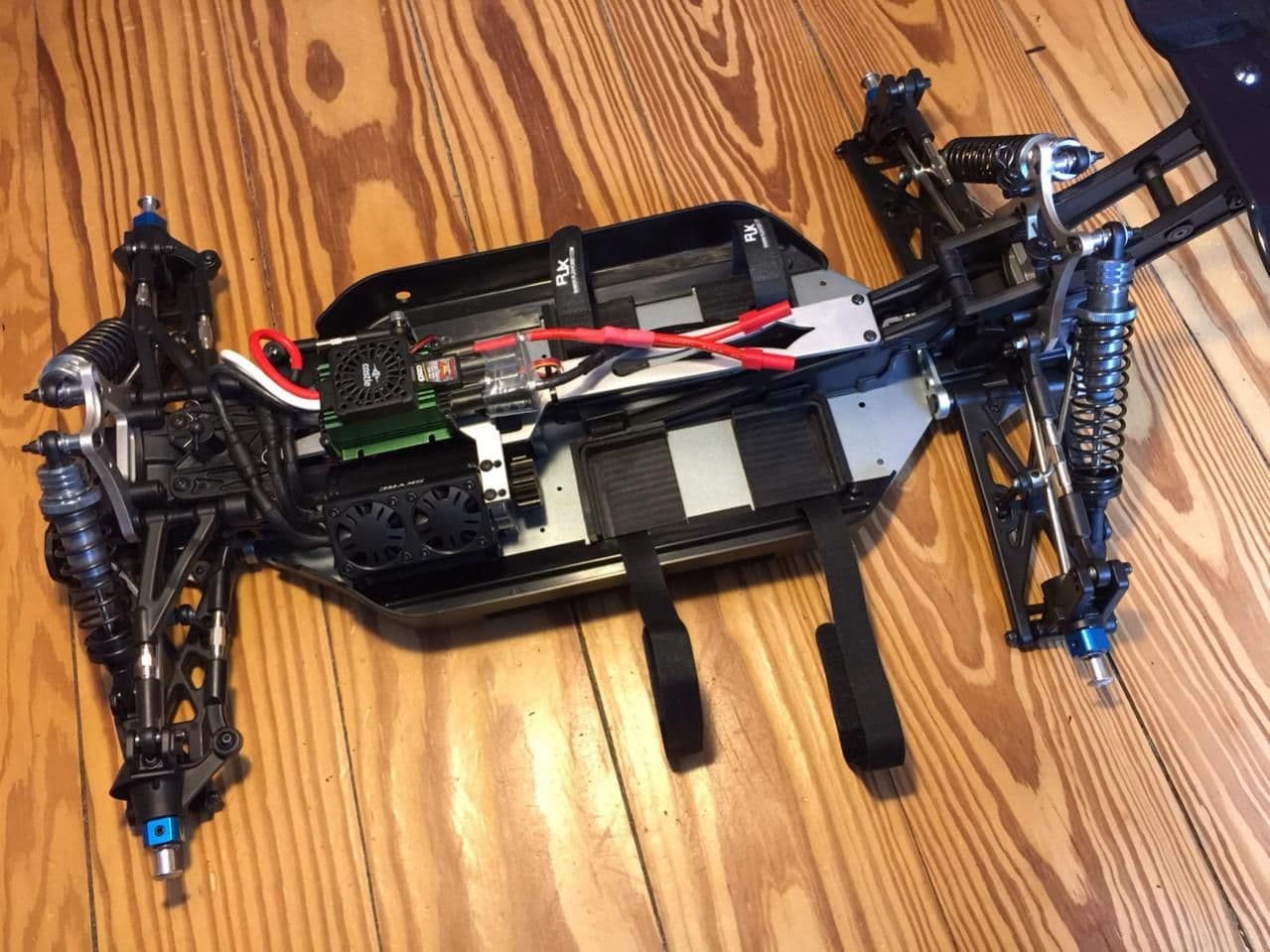

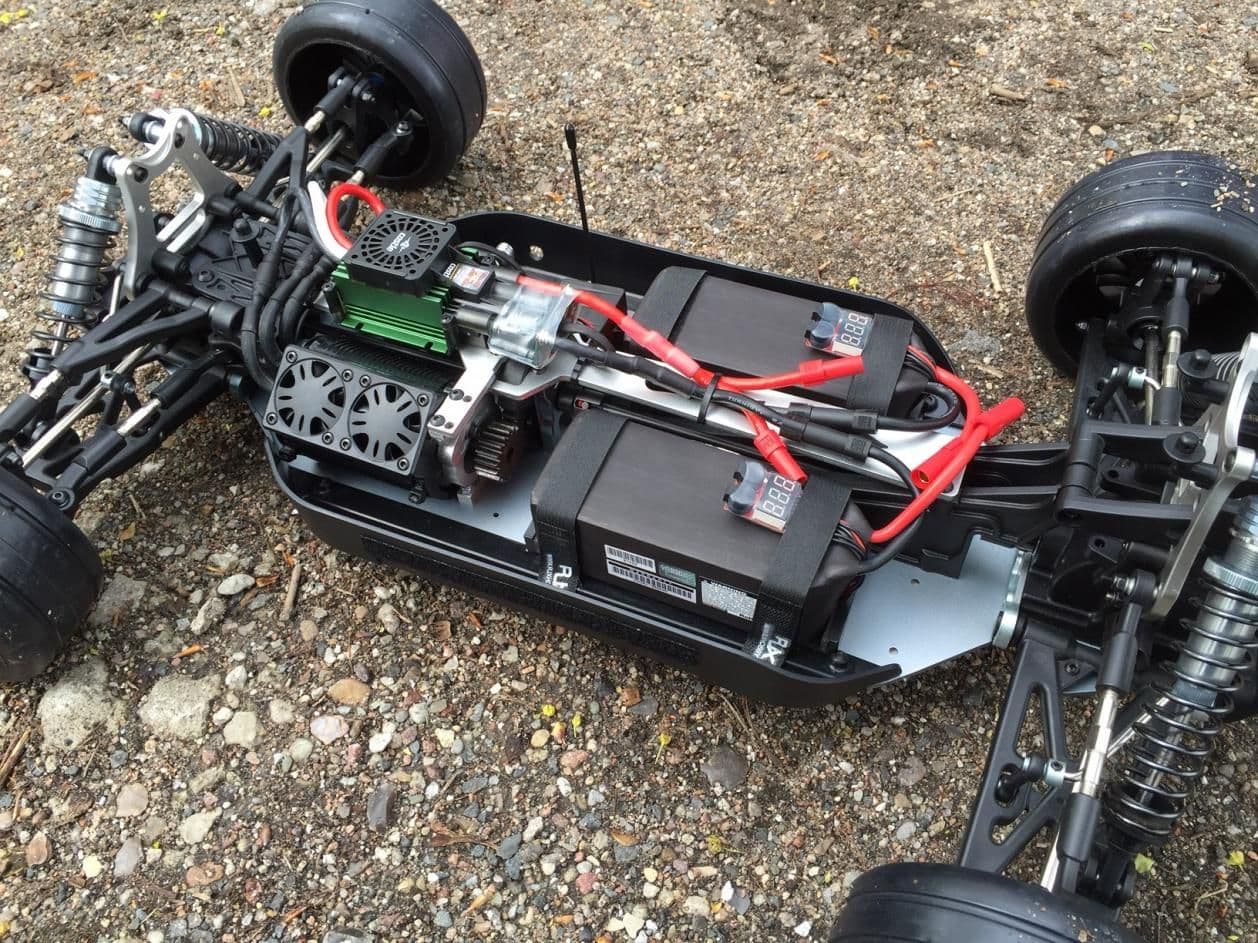

Hi guys, I'm new here and thought I'd show you what I'm working on. Still need to work on the battery trays a bit, but it's slowly coming to life now. It's cool to have a dedicated forum for this platform and this forum has been a great help already to get me up to speed on the car, so thanks for that and I hope you are going to enjoy my thread!

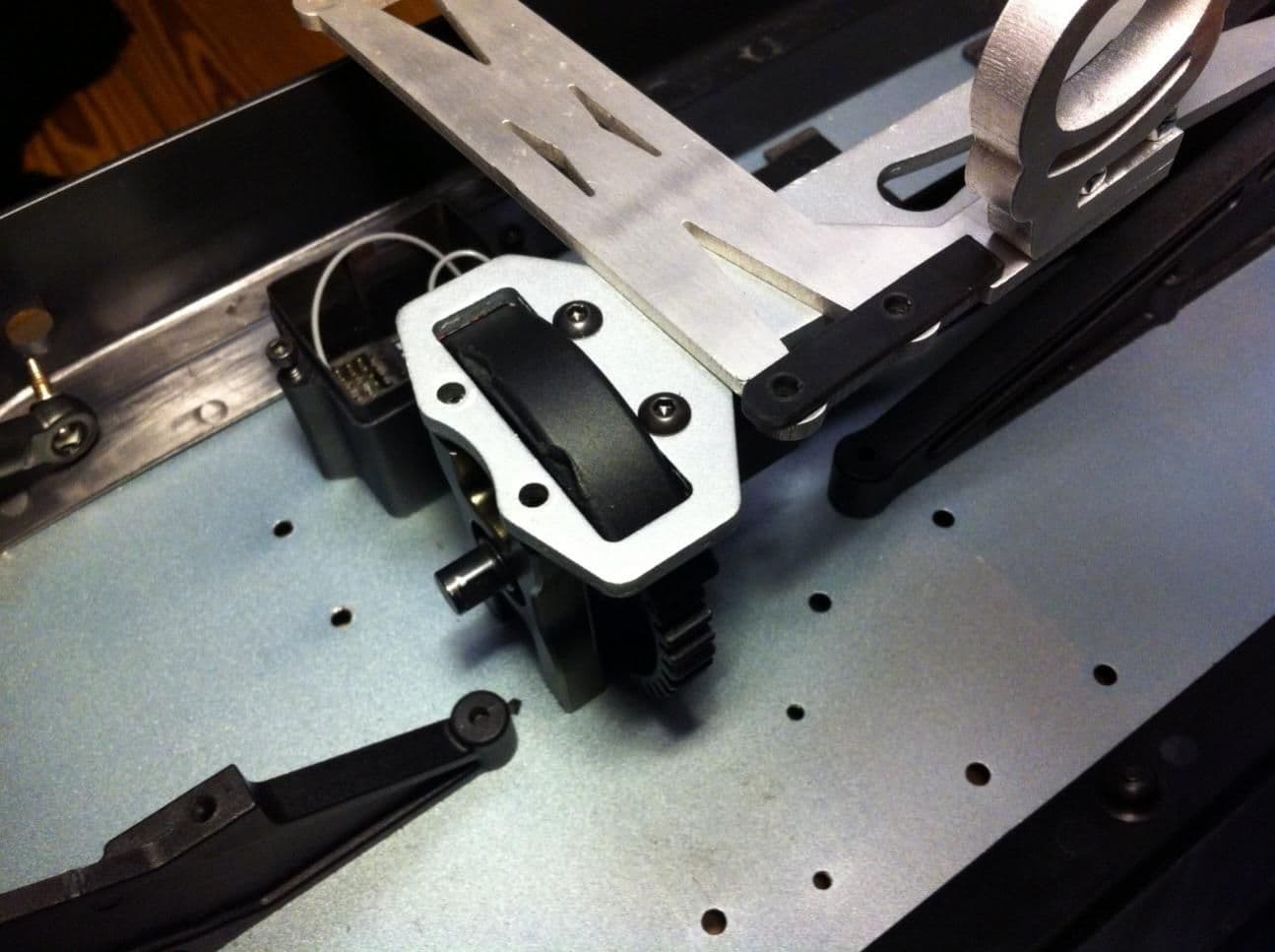

Motor mount:

I opted for the Kershaw mount, because of availability and price. It takes a little bit of fiddling to use it with gear cover and have both the top plates nice and level, but that's part of the fun. The 2 mounting positions to allow for motors longer than 106 mm looks nice on paper, but in practice, with the mount in rear (2028, 58110 size) position, the mounting screws basically limit pinion sizes to max 13T, unless running the gears with a bit of off-set... Means the need for big and heavy tires to gear up with mount in 2028/58110 position, or using >8S, but those ESCs are still way to scarce unfortunately.

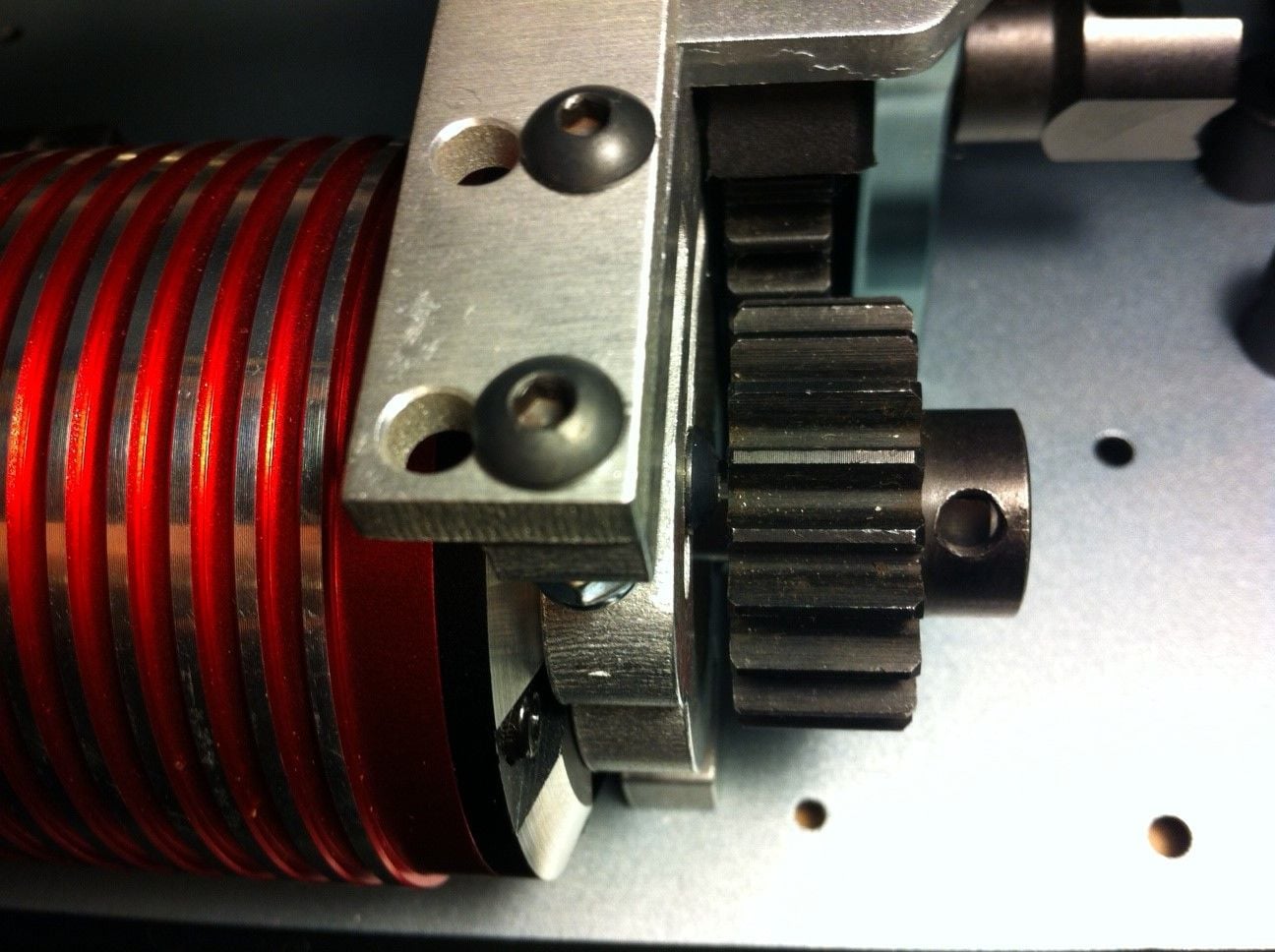

Motor(s):

Stock motor appears to be a core-less 2-pole, seems a bit small for a big car like this. I'll start my testing with a TP5670 (55x90mm, 962g, probably a 6D wind -judging from kv check- but not 100% sure) and LBP5898-1100kv (1096g). I also have a LBP-58110-950kv (1248 g), but for now, that needs too big/heavy tires to get the gearing I want, based on the pinion limit of the KD mount.

Did quick little kv test. No-load current of the TP5670 is quite high, over 2 times as high as the Leopard. >10A at 22V is >220W doing nothing but generating heat. That's about 3 proper soldering irons . During the no-load kv test, the 960 g TP5670 accelerated noticeably more violently than the 1100 g LBP5898, suggesting higher Torque.

. During the no-load kv test, the 960 g TP5670 accelerated noticeably more violently than the 1100 g LBP5898, suggesting higher Torque.

Anyway, looking forward to some more testing to see how things will be under load. Seems the Leo is actually going to be more efficient at lower loads; question becomes at what loads they cross-over. From what I've seen, I'm expecting the TP to hold RPM better than the Leo, which at some point will drive the Leo to lower efficiency... at least that's how I think it works...

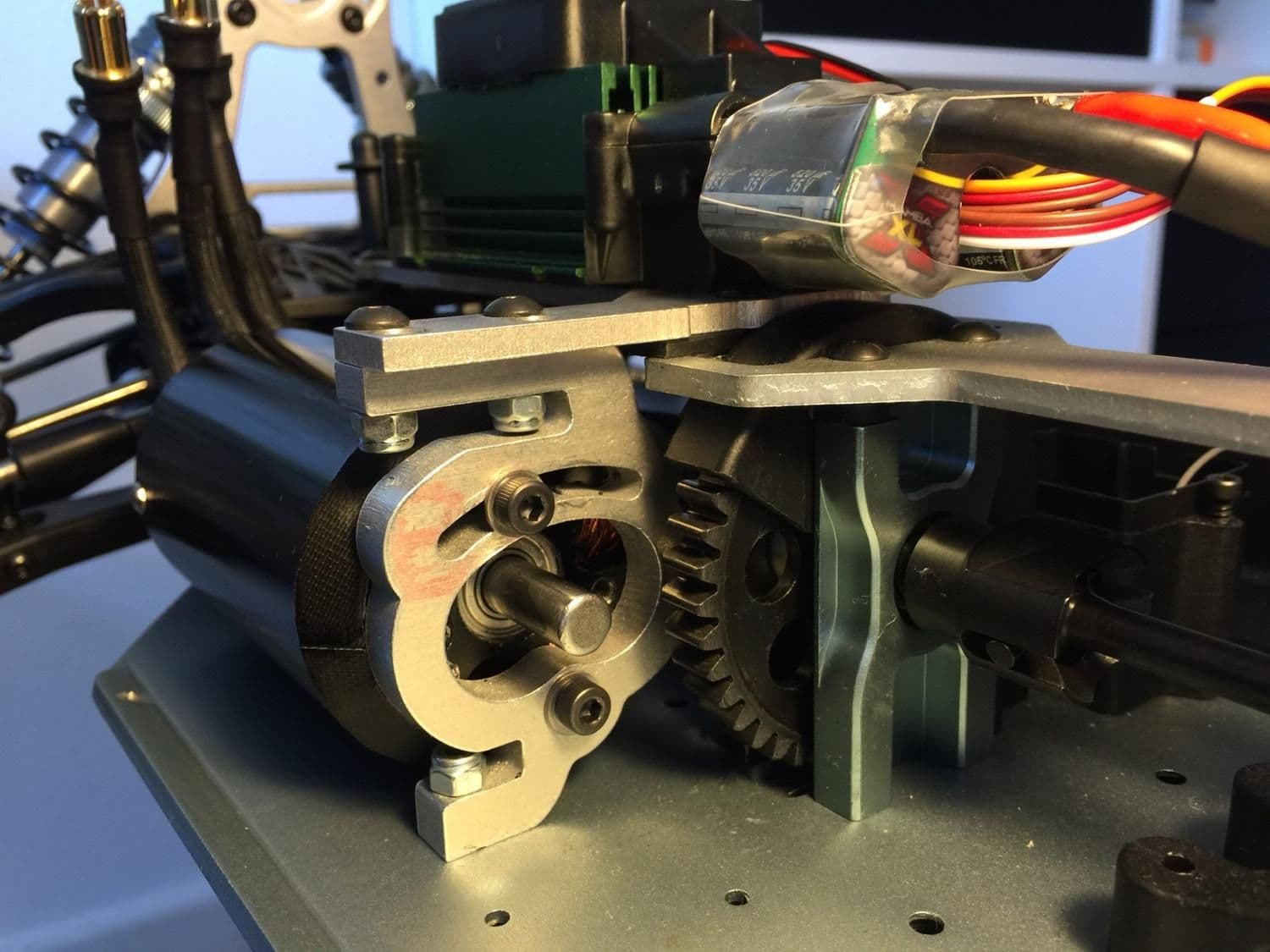

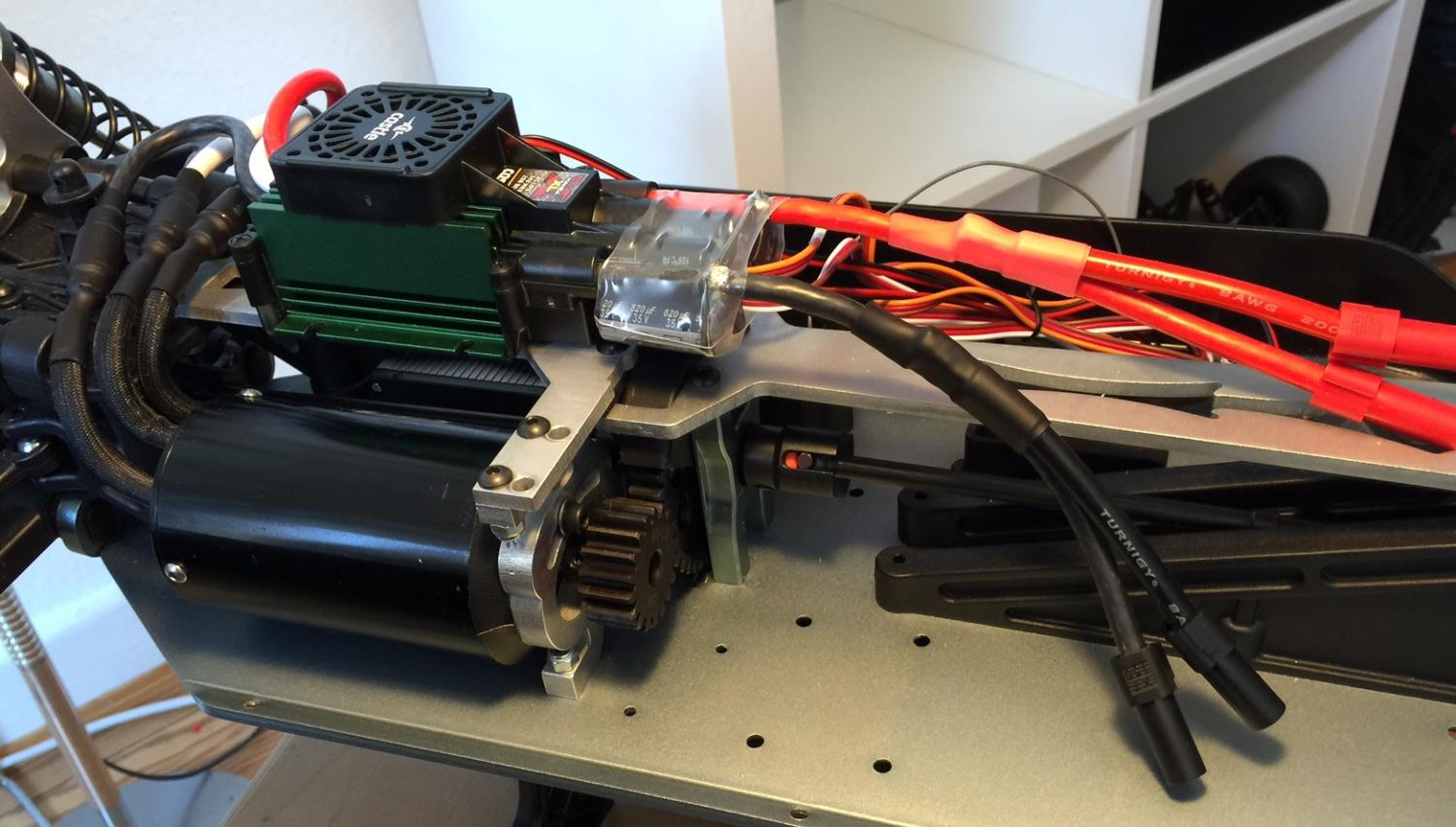

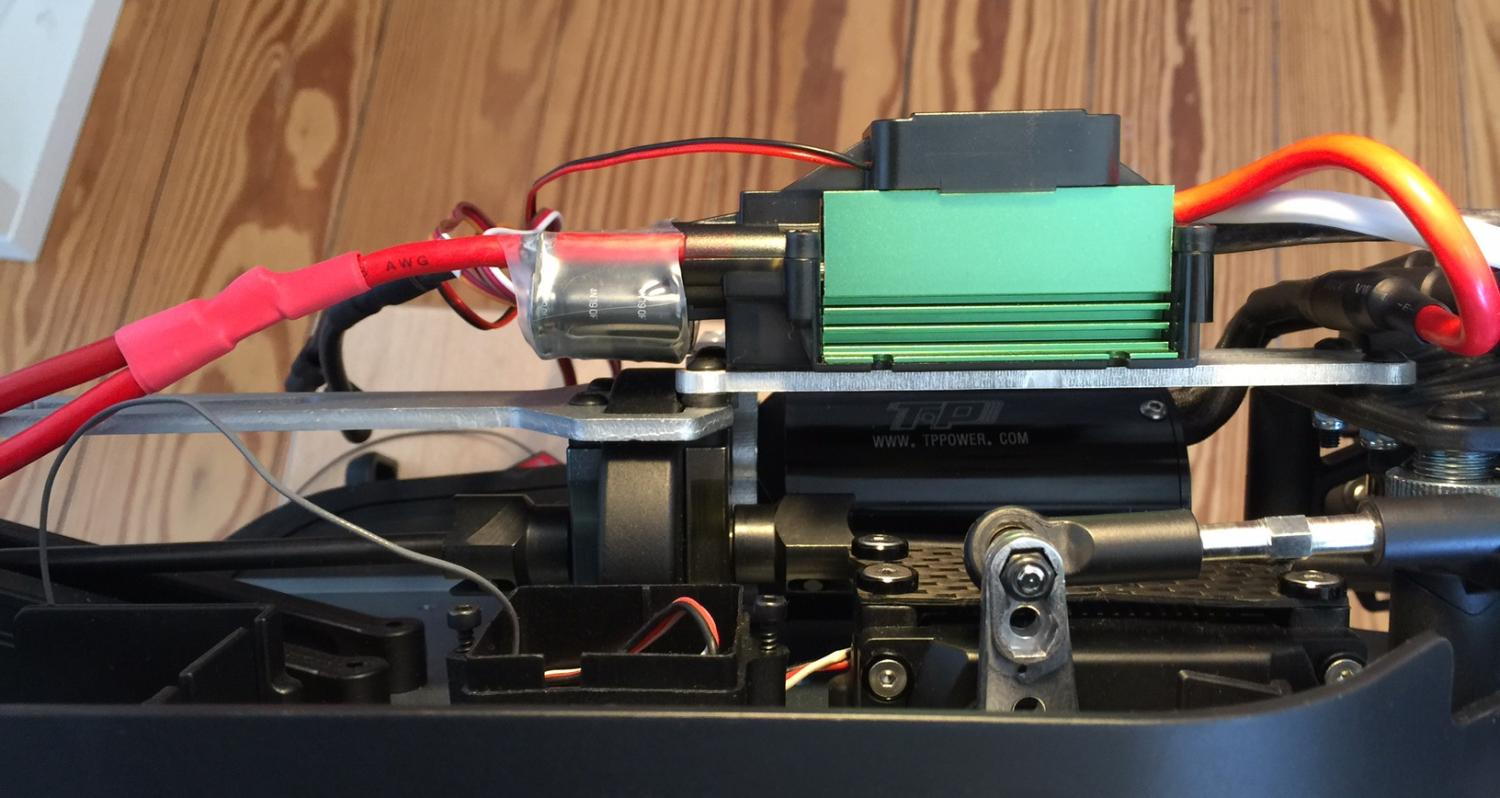

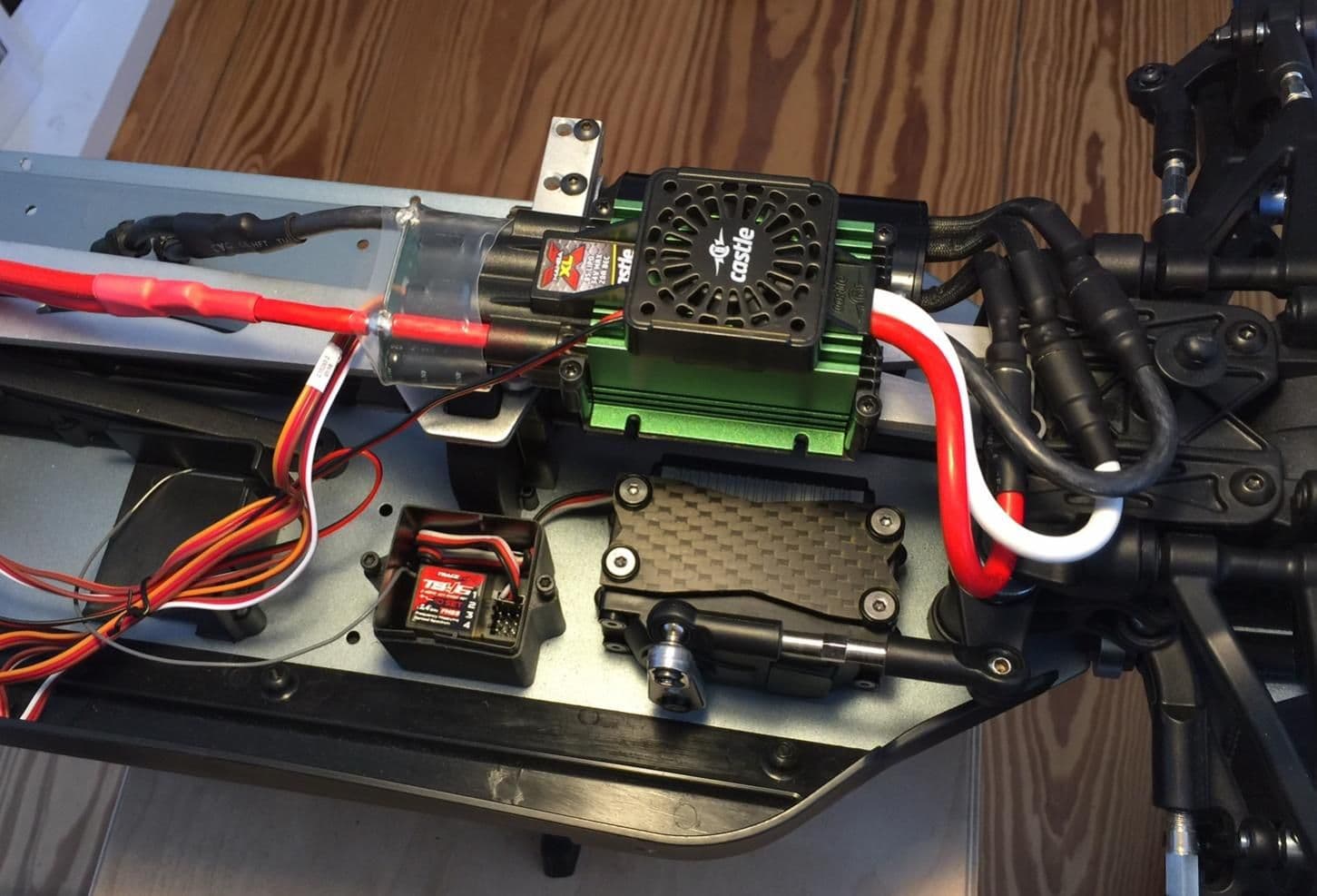

ESC:

Will try the updated Mamba XL (X). Thought about getting that new Toro Beast ESC, but reading how SkyRC seems to have screwed up the accompanying software and datalogging, made me choose for XLX, although I have seen the XL2 getting a bit hot in Othello's Carson Dirt Attack - which is same car with different badge. Castle's datalogging keeps being one of the big selling points for me though.

Didn't open it up to check the inside caps, but the new XLX front caps are 2x1500uF instead of the 2x680uF of the XL2. The integrated cappack is 4x820uF. So, assuming internal caps are still 2x560uF like with XL2, total capacitance is 7400uF, compared to 2480uF of the standard XL2... that should produce some manly sparks!

Although the added cappack seems like a bit of an afterthought, I think it looks pretty decent (at least better than when I'd have to add a bunch of caps myself) and the added length doesn't matter for this car; in fact, the form factor of the XLX works pretty well here, and I can (just, but) still fit the buggy body with the ESC mounted on the front top-plate.

Batteries:

I have a couple of 5Ah 6S Turnigy Heavy Duty packs from my 1/8 scales, which I will start off with, running parallel (10Ah 6S total). For 8S I'll either be using 2x2 4Ah 4S (8Ah 8S total) Turnigy Heavy Duty packs, or the new Turnigy Graphene packs, when they become available and performance looks as good as the specs.

Gearing:

Gearing chart with resulting no-load nominal-Voltage (i.e., 3.7V/cell) wheel-speeds (NLWS) for measured kvs below. 13/41 on 155mm stock tires (80-109 km/h no-load, depending Voltage and motor) looks like good start for off-road, and 18/41 on 138mm GRP F1 tires (98-135 km/h no-load, depending on Voltage and motor) for on-road.

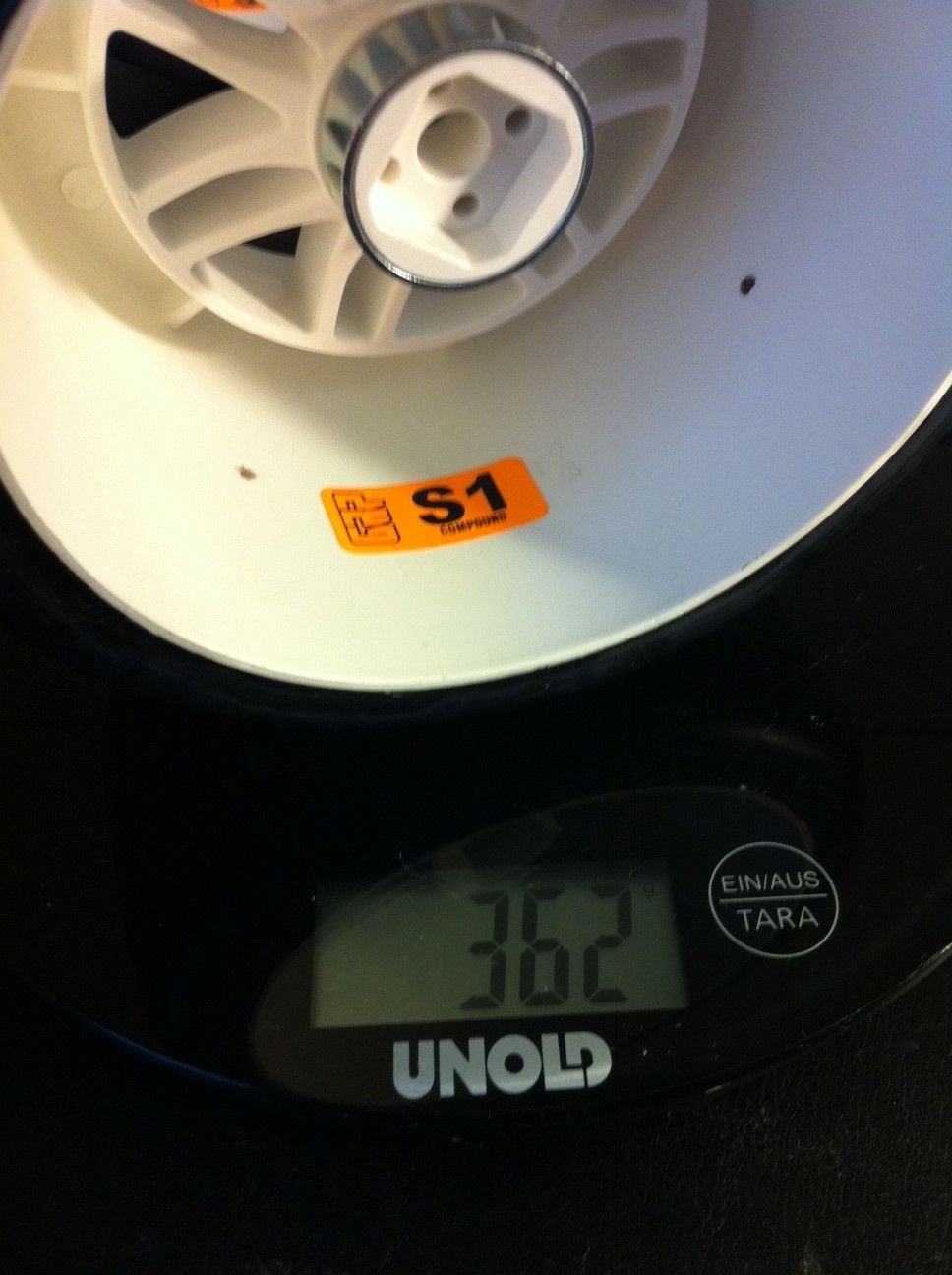

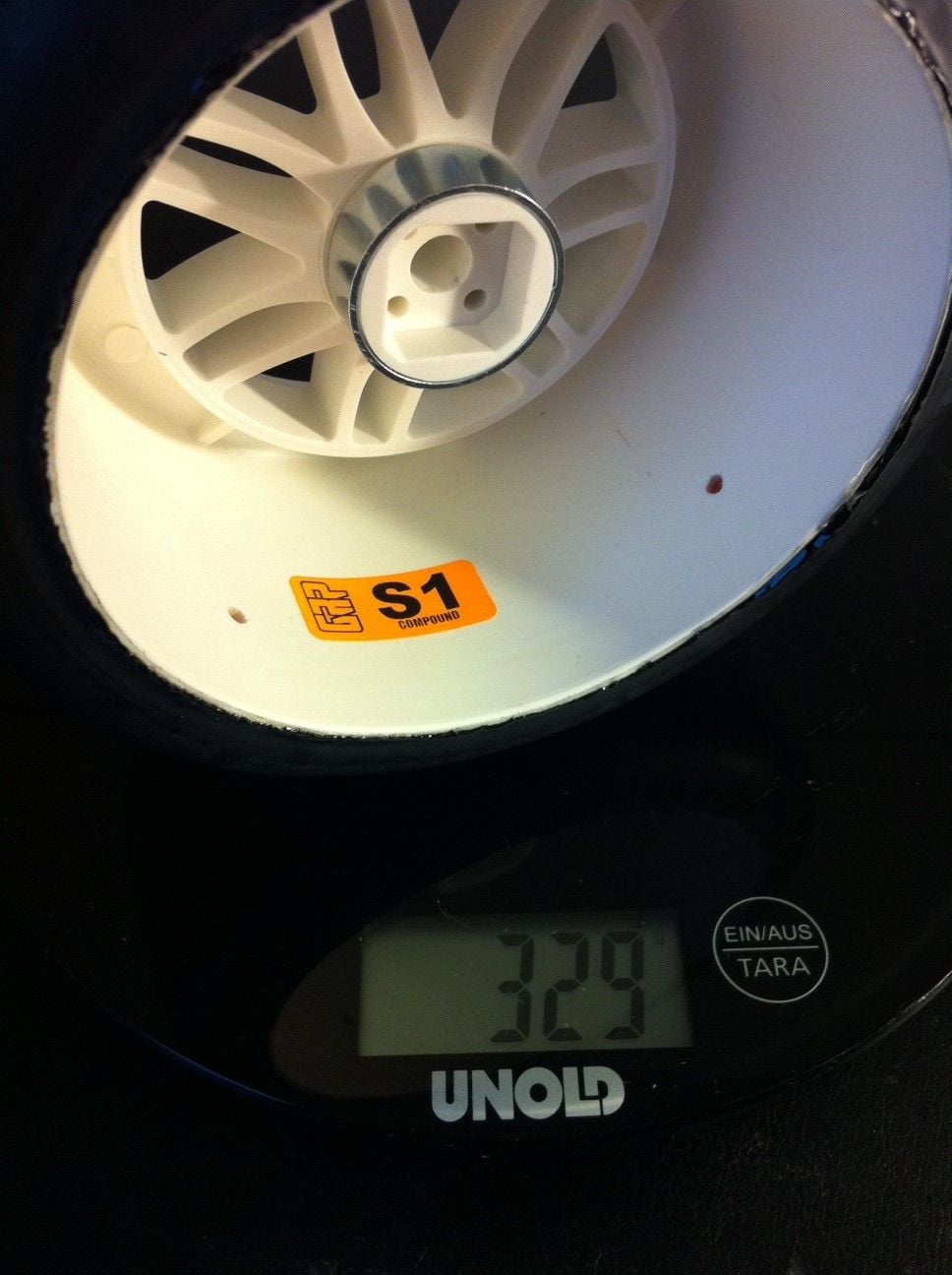

Wheels:

I like light and smaller wheels, so for now I'll stick to the stock and FG style tires, instead of going for the Baja 24mm hexes. Disadvantage of the FGs is they need some more modification with the new M10-stub axles (I still have a couple of M6-stub axles) and the off-set of FG style rims is way too big...

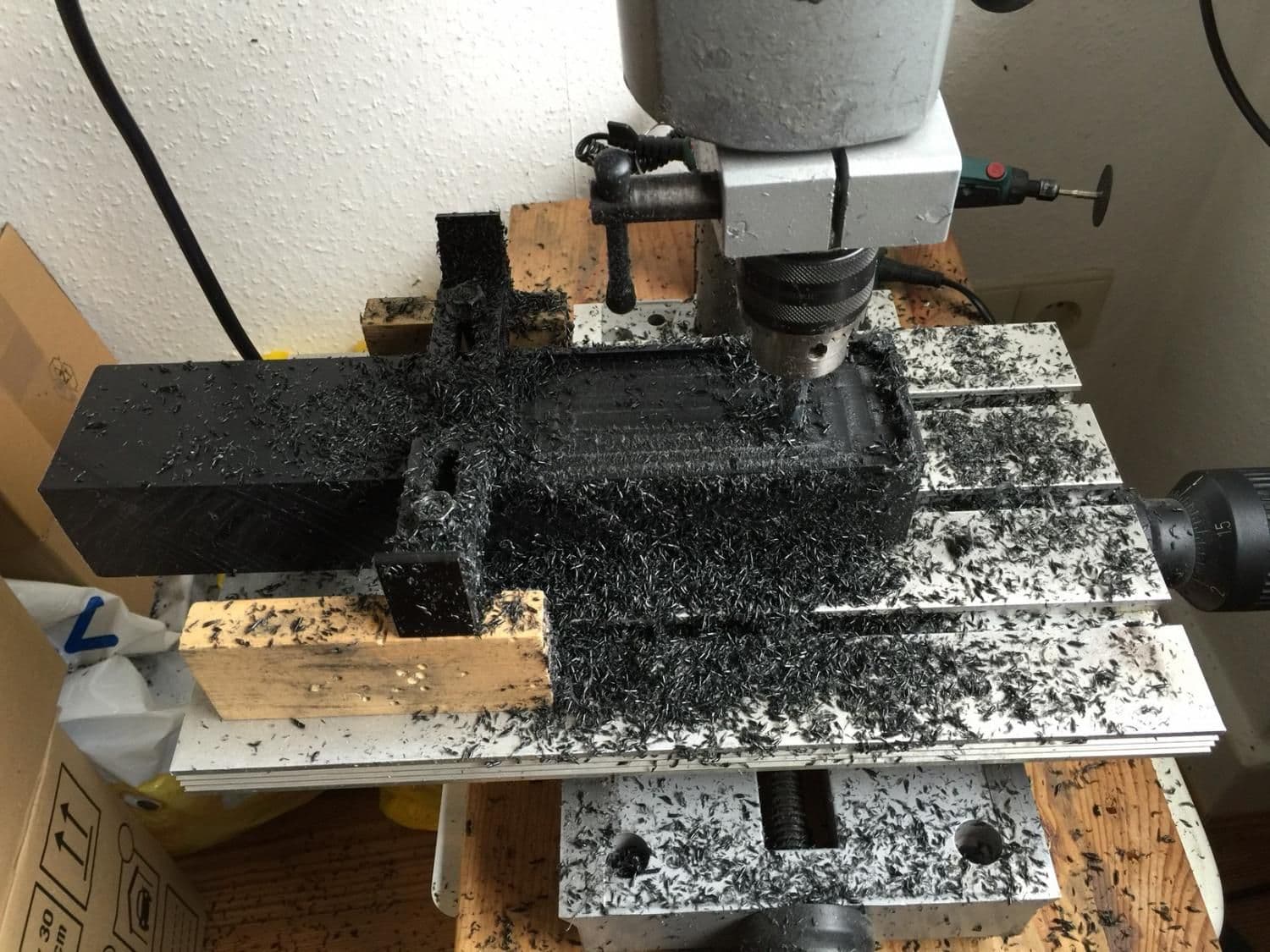

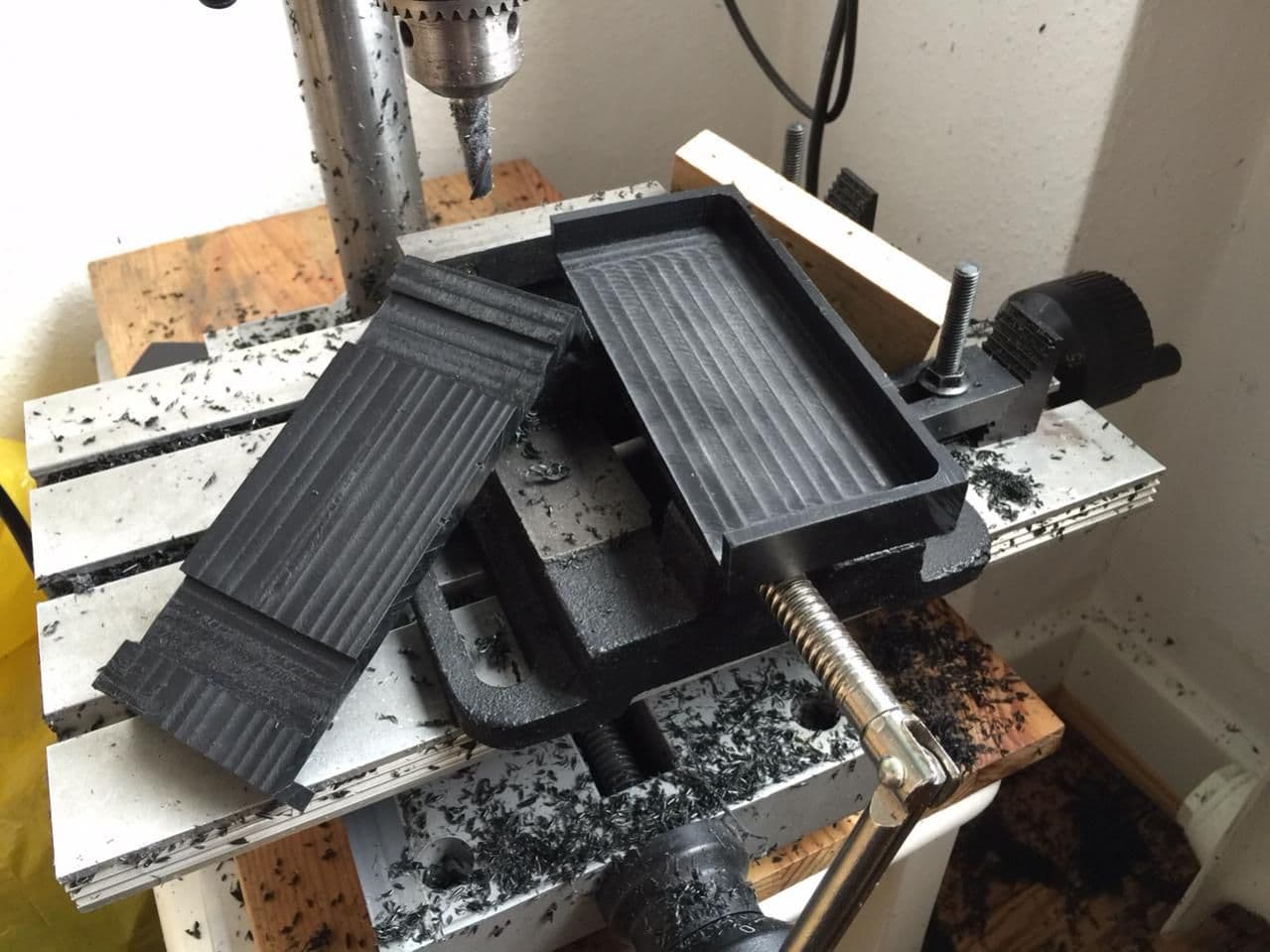

Wheel-bearing spacers:

I noticed the 18mm squares get pushed into the bearings when tightening the wheel-nuts hard, resulting in a lot of lateral force on the wheel-bearings (inner races being pulled together), causing the bearings to not run freely. I used a pipe-cutter and some simple 14-10mm alu tube to make spacers that fill the gap between the inner bearing races; now, no matter how hard I crank-down the wheel-nuts, the bearings keep running nice and smoothly.

Pics (more to come below):

No-load kv test, TP5670 (left) vs LBP5898-1100 (right), RPM scale is showing "electrical RPM" (ERPM: as if it were 2-poles):

Gearing-chart, based on measured kvs:

DIY wheel-bearing spacers (go between wheel-bearings to prevent inner races being pulled together):

Hi guys, I'm new here and thought I'd show you what I'm working on. Still need to work on the battery trays a bit, but it's slowly coming to life now. It's cool to have a dedicated forum for this platform and this forum has been a great help already to get me up to speed on the car, so thanks for that and I hope you are going to enjoy my thread!

Motor mount:

I opted for the Kershaw mount, because of availability and price. It takes a little bit of fiddling to use it with gear cover and have both the top plates nice and level, but that's part of the fun. The 2 mounting positions to allow for motors longer than 106 mm looks nice on paper, but in practice, with the mount in rear (2028, 58110 size) position, the mounting screws basically limit pinion sizes to max 13T, unless running the gears with a bit of off-set... Means the need for big and heavy tires to gear up with mount in 2028/58110 position, or using >8S, but those ESCs are still way to scarce unfortunately.

Motor(s):

Stock motor appears to be a core-less 2-pole, seems a bit small for a big car like this. I'll start my testing with a TP5670 (55x90mm, 962g, probably a 6D wind -judging from kv check- but not 100% sure) and LBP5898-1100kv (1096g). I also have a LBP-58110-950kv (1248 g), but for now, that needs too big/heavy tires to get the gearing I want, based on the pinion limit of the KD mount.

Did quick little kv test. No-load current of the TP5670 is quite high, over 2 times as high as the Leopard. >10A at 22V is >220W doing nothing but generating heat. That's about 3 proper soldering irons

Anyway, looking forward to some more testing to see how things will be under load. Seems the Leo is actually going to be more efficient at lower loads; question becomes at what loads they cross-over. From what I've seen, I'm expecting the TP to hold RPM better than the Leo, which at some point will drive the Leo to lower efficiency... at least that's how I think it works...

ESC:

Will try the updated Mamba XL (X). Thought about getting that new Toro Beast ESC, but reading how SkyRC seems to have screwed up the accompanying software and datalogging, made me choose for XLX, although I have seen the XL2 getting a bit hot in Othello's Carson Dirt Attack - which is same car with different badge. Castle's datalogging keeps being one of the big selling points for me though.

Didn't open it up to check the inside caps, but the new XLX front caps are 2x1500uF instead of the 2x680uF of the XL2. The integrated cappack is 4x820uF. So, assuming internal caps are still 2x560uF like with XL2, total capacitance is 7400uF, compared to 2480uF of the standard XL2... that should produce some manly sparks!

Although the added cappack seems like a bit of an afterthought, I think it looks pretty decent (at least better than when I'd have to add a bunch of caps myself) and the added length doesn't matter for this car; in fact, the form factor of the XLX works pretty well here, and I can (just, but) still fit the buggy body with the ESC mounted on the front top-plate.

Batteries:

I have a couple of 5Ah 6S Turnigy Heavy Duty packs from my 1/8 scales, which I will start off with, running parallel (10Ah 6S total). For 8S I'll either be using 2x2 4Ah 4S (8Ah 8S total) Turnigy Heavy Duty packs, or the new Turnigy Graphene packs, when they become available and performance looks as good as the specs.

Gearing:

Gearing chart with resulting no-load nominal-Voltage (i.e., 3.7V/cell) wheel-speeds (NLWS) for measured kvs below. 13/41 on 155mm stock tires (80-109 km/h no-load, depending Voltage and motor) looks like good start for off-road, and 18/41 on 138mm GRP F1 tires (98-135 km/h no-load, depending on Voltage and motor) for on-road.

Wheels:

I like light and smaller wheels, so for now I'll stick to the stock and FG style tires, instead of going for the Baja 24mm hexes. Disadvantage of the FGs is they need some more modification with the new M10-stub axles (I still have a couple of M6-stub axles) and the off-set of FG style rims is way too big...

Wheel-bearing spacers:

I noticed the 18mm squares get pushed into the bearings when tightening the wheel-nuts hard, resulting in a lot of lateral force on the wheel-bearings (inner races being pulled together), causing the bearings to not run freely. I used a pipe-cutter and some simple 14-10mm alu tube to make spacers that fill the gap between the inner bearing races; now, no matter how hard I crank-down the wheel-nuts, the bearings keep running nice and smoothly.

Pics (more to come below):

No-load kv test, TP5670 (left) vs LBP5898-1100 (right), RPM scale is showing "electrical RPM" (ERPM: as if it were 2-poles):

Gearing-chart, based on measured kvs:

DIY wheel-bearing spacers (go between wheel-bearings to prevent inner races being pulled together):

Last edited by a moderator: